High Performance ASME Flanges

We serve industries such aviation fueling, chemical processing, and well drilling with ASME flanges that meet the most demanding jobsite and system requirements. Whether you’re replacing a failed component or building a new system from the ground up, we have the inventory and experience to deliver exactly what your project calls for.

Fast lead times

Competitive pricing

Premium flanges

Our ASME Flanges

Each flange is manufactured to exacting tolerances, machined to meet precise dimensional requirements, and inspected to ensure it performs reliably in service. Whether your project involves high-pressure steam, corrosive chemicals, or structural piping, we’ll help you choose the right flange for the job.

MOST POPULAR INDUSTRIAL PIPE FLANGES

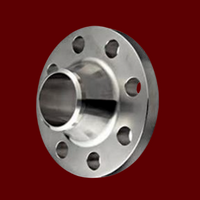

WELD NECK FLANGE

The most frequently requested flange, the Weld Neck Flange features a neck extension and weld bevel. Provides a natural form connection ideal for larger, high-pressure applications.

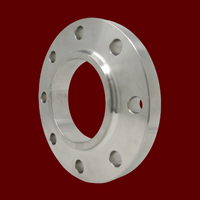

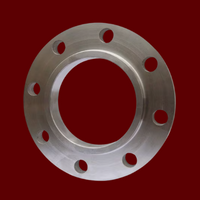

SLIP ON FLANGE

A simple alternative to the Weld Neck flange, a Slip On Flange is designed to accept the pipe into the center/bore, allowing welding around the outer diameter of the pipe.

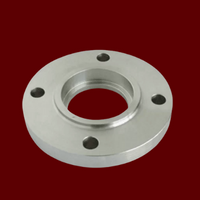

BLIND FLANGE

Designed to cap off a line, a Blind Flange has no bore or inner diameter. They are often altered to include NPT threads or custom bore holes to function as hubless Slip On flanges.

SOCKET WELD / COUNTER BORE FLANGE

Socket weld flanges, offer a comparably efficient option for flange connections that demand a reduced spatial footprint compared to the traditional weld neck flanges.

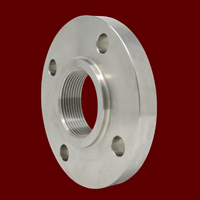

THREADED COMPANION FLANGE

Threaded or Companion Flanges contain a female NPT threaded center for connection to male threaded piping. These flanges are commonly implemented in reducing connections.

LAP JOINT FLANGE

Lap Joint Flanges are intended to saddle over a stub end fitting. They feature an extended hub and a machined radius at the base of the flat face.