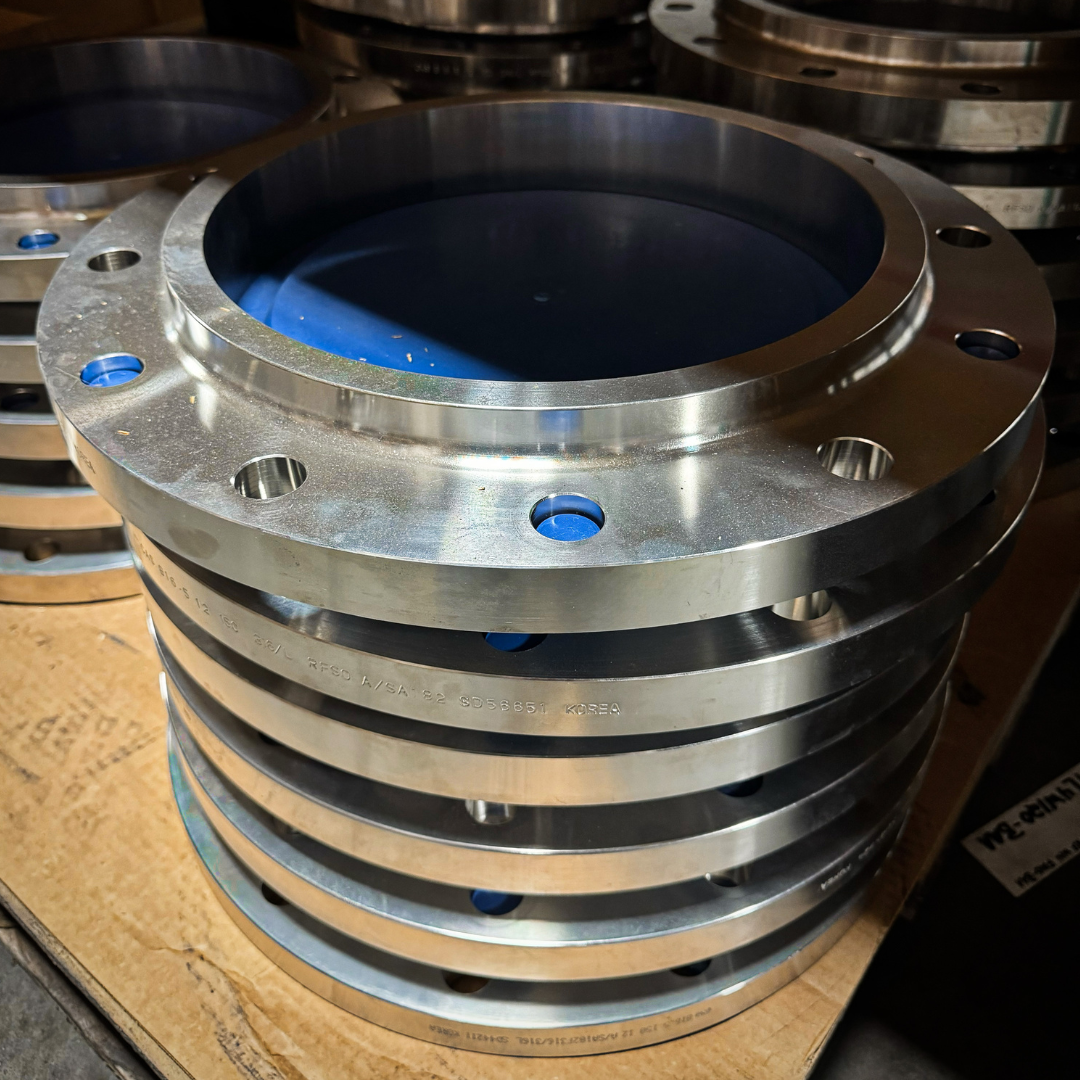

SLIP ON FLANGES

Slip-on flanges, a widely embraced type of pipe flange, are designed to accommodate the insertion of a pipe into the center bore of the flange. This facilitates welding around both the Outer Diameter (OD) of the pipe and the inner side of the connection.

The slip-on flange serves as a straightforward and effective alternative to the weld neck flange. It lacks a weld bevel, which offers the advantage of adjusting the pipe’s length in relation to its position within the flange. The bore of the slip-on flange provides ample space to accommodate the corresponding pipe. This configuration grants the welder and fabricator sufficient room to establish the connection.

→ SLIP ON FLANGE FEATURES

This flange variation finds extensive usage in applications involving lower pressures. In most slip-on style flanges, a hub is present, which often appears dimensionally similar to a raised face. In cases where space is restricted and the circumstances allow for a “ring style” slip-on, it can be supplied without a hub.

While the hub-equipped style is more prevalent when discussing slip-ons, a hubless ring-style slip-on still falls within the realm of slip-on flanges and can be specified as needed.

In instances demanding higher pressure ratings, slip-ons are frequently crafted with the height resembling that of a lap joint, enhancing the connection quality. When hub height isn’t a constraint and a lap joint isn’t readily accessible, customers occasionally choose a slip-on designed in a lap joint style with a machined hub.