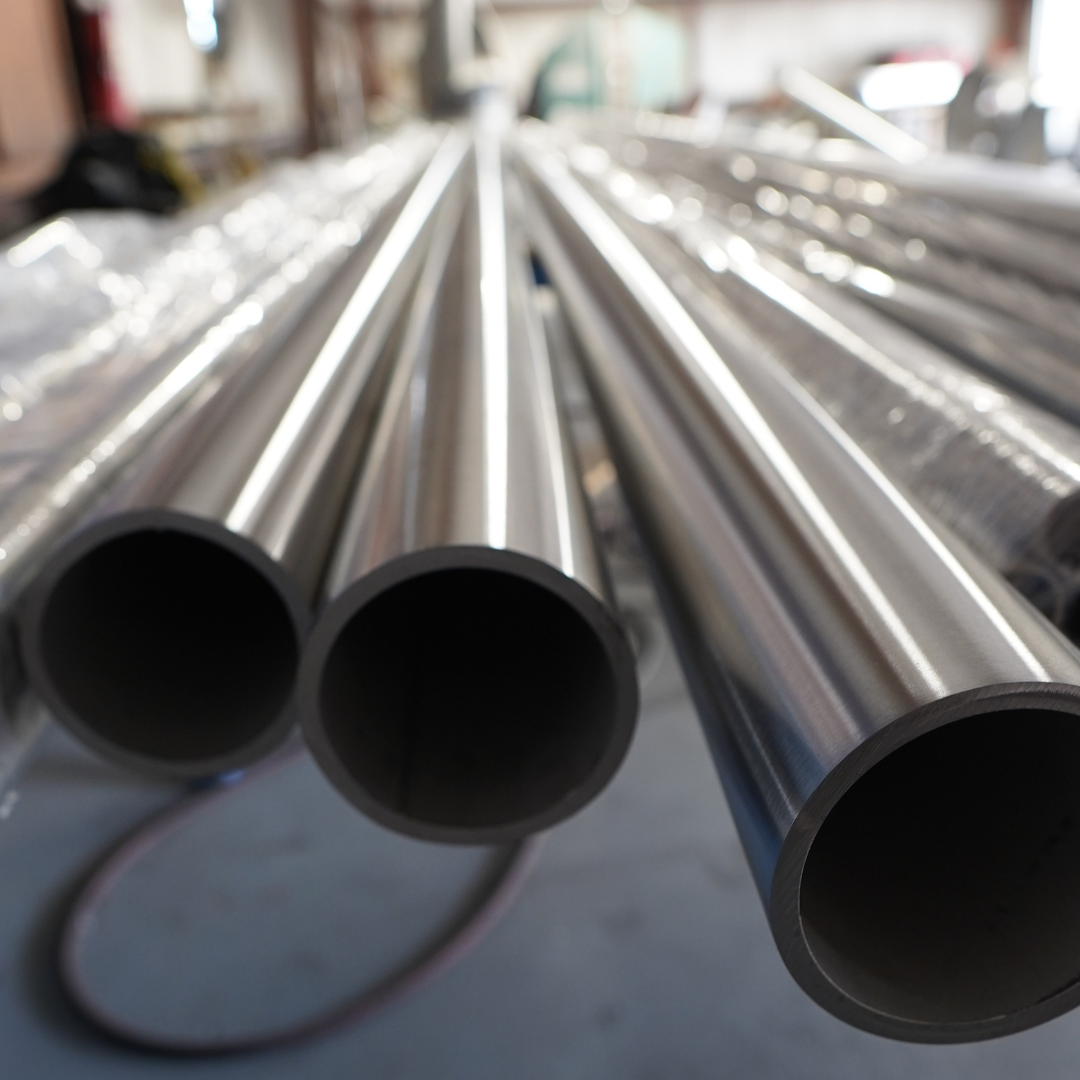

STAINLESS STEEL POLISHING SERVICES

Cole Industrial stands at the forefront of stainless steel polishing, excelling in the refinement of stainless steel tube, pipe, and other products. Our stainless steel pipe polishing services include techniques tailored to suit diverse needs. Our team of specialists is always ready to assist in selecting the most suitable polishing method, considering your specific application and budget constraints.

SUPERIOR PRODUCTS AT COMPETITIVE PRICES

At Cole Industrial Shaw Stainless, our commitment to innovation is unwavering. We are dedicated to consistently exploring and integrating advanced technologies to elevate the quality of our polished stainless steel products.

STAINLESS STEEL POLISHING SERVICES: OUR PRODUCTS

Cole Industrial excels in providing comprehensive stainless steel polishing services, catering to a wide array of products including the following:

Our state-of-the-art polishing techniques are meticulously applied to each of these products, ensuring a flawless finish and superior quality. Each product benefits from our advanced polishing techniques, which are tailored to meet the specific needs and standards of our diverse clientele, ensuring satisfaction in both functionality and appearance.

OUR PROCESS: STAINLESS STEEL POLISHING

The stainless steel polishing process is a multi-stage procedure designed to enhance the appearance, durability, and overall quality of stainless steel products.

Surface Cleaning: The initial step involves thoroughly cleaning the stainless steel surface to remove any dirt, grease, or other contaminants. This is crucial for ensuring a uniform polish.

Rough Grinding: This stage involves using coarse abrasive materials to remove the outer layers of the steel, including any existing oxidation, scratches, or weld marks. This process is typically done with grinding wheels or belts, and it’s important to maintain consistency to avoid uneven surfaces.

Sanding: After the rough grinding, finer grit sanding is performed. This step smooths out the scratches from the initial grinding. Different grit sizes may be used in succession to gradually refine the surface.

Buffing: Buffing involves the use of a buffing wheel along with a polishing compound. This step is crucial for achieving a smooth, mirror-like finish. The compound used in buffing fills in any microscopic scratches and buffs the surface to a high shine.

Final Cleaning: Once the desired level of polish is achieved, the stainless steel is cleaned again to remove any residual polishing compound or dust.

Inspection and Quality Control: The final step involves a thorough inspection of the polished stainless steel to ensure that it meets the required standards of quality and finish.

CONTACT US TODAY FOR A CUSTOM QUOTE

Throughout the stainless steel polishing process, different grades of polish can be achieved depending on the desired outcome.

For instance, a brushed finish requires different techniques compared to a mirror finish.

The choice of abrasives, buffing compounds, and the level of manual labor involved can vary significantly based on the final application of the product, whether it’s for aesthetic purposes, corrosion resistance, or other functional uses.