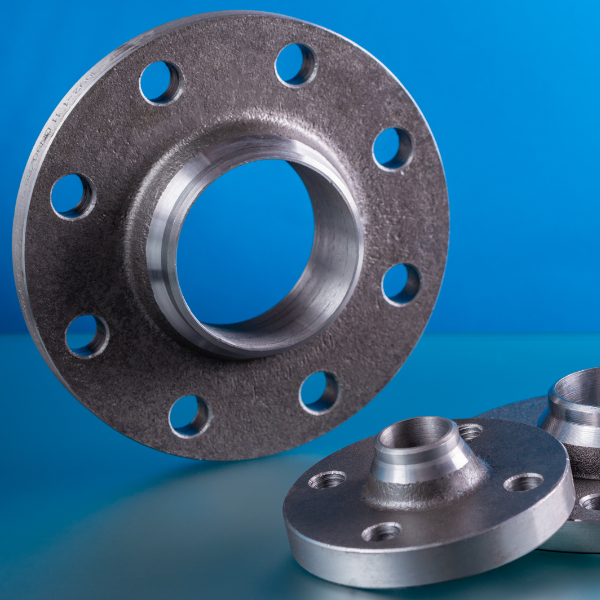

WELD NECK FLANGE

Weld neck flanges stand as the most favored among flange types due to their extended neck featuring a weld bevel at its tip. This particular flange design is crafted for seamless butt welding to pipe, creating a remarkably robust and inherently smooth connection.

As dimensions grow larger and pressure requirements become more demanding, the weld neck flange takes center stage as the preferred choice for forging these connections. If solitary bored flange style were to govern modern applications, the weld neck would undoubtedly claim its position as the prime selection.

→ WELD NECK FLANGE FEATURES

The weld neck flange also boasts a notable feature in the form of its tapered hub. This design characteristic facilitates a gradual distribution of pressure forces, ensuring a smoother transition from the pipe to the flange’s base. This structural advantage is particularly beneficial in environments characterized by elevated pressure and temperature conditions, helping to absorb some of the impact associated with such usage. The presence of extra steel material along the hub transition further mitigates mechanical stresses.

Given the prevalence of higher pressure classes, weld neck flanges are predominantly manufactured with a ring type joint facing, often referred to as an RTJ face. This specific sealing surface accommodates the use of a metallic gasket that can be compressed within the grooves of the connecting flanges. This arrangement forms an exceptional seal, supplementing the robust weld bevel connection to the pressurized pipe assembly. In scenarios where utmost reliability is imperative, an RTJ weld neck flange coupled with a metallic gasket emerges as the primary preference.

LONG WELD NECK FLANGE

Frequently referred to as nozzle flanges or “long neck” flanges, these components were meticulously crafted to cater to the requirements of the pressure vessel and tank fabrication sector. Typically fashioned as a unified construction, their purpose is to serve as a substitute for the conventional combination of a weld neck and pipe weld. The distinctive hallmark of this flange style is its elimination of the obligatory weld connection.

As indicated in ASME B16.5 subsection 2.8, these flange configurations are alternatively recognized as “straight hub welding flanges.” They receive limited elaboration within the governing specification, primarily because the design specifics of long weld necks are tailored to individual applications, aligning with the specific engineering prerequisites of a particular pressure vessel or tank. The operational pressure, temperature, and substance contained within the vessel collectively play a pivotal role in determining the precise form of long weld neck flange connection essential for the given scenario.

→ LONG WELD NECK FLANGE FEATURES

Typically, long weld neck flanges feature a single straight bore with a squared termination (in contrast to the customary weld neck bevel). The diameter of the bore for the long weld neck usually matches the nominal pipe size precisely, although adjustments can be made as needed.

The overall length of the nozzle flange is also determined by the end user, and the nozzle’s body can be adapted to conform to existing sizes or tailored for custom dimensions, enhancing its reinforcement. The junction between the neck’s base and the flange’s base is subtly rounded, addressing the abrupt perpendicular connection between these components and enhancing the concept of a unified and strengthened single-piece construction.

FREQUENTLY ASKED QUESTIONS

WHAT IS A WELD NECK FLANGE?

A weld neck flange is a type of flange designed for use in high-pressure applications, where secure, leak-free connections are essential. It has a long, tapered hub that is welded to the pipe, providing additional strength and stability.

WHAT ARE THE ADVANTAGES OF A WELD NECK FLANGE?

Weld neck flanges are highly durable and resistant to fatigue due to their long, tapered hub. They provide a smooth transition from the flange to the pipe, reducing stress concentration. This makes them ideal for high-pressure and high-temperature applications.

IN WHAT INDUSTRIES ARE WELD NECK FLANGES COMMONLY USED?

Weld neck flanges are used across various industries, including oil and gas, petrochemical, power generation, and water treatment. Their robust design makes them suitable for any industry where high-pressure and high-stress connections are required.

WHAT MATERIALS ARE WELD NECK FLANGES MADE FROM?

Weld neck flanges are typically made from materials like carbon steel, stainless steel, and alloy steel. Cole Industrial offers a variety of material options to meet different environmental and operational needs.

HOW ARE WELD NECK FLANGES INSTALLED?

Weld neck flanges are installed by welding the flange’s hub to the pipe. This requires a skilled welder to ensure a proper, secure fit and to maintain the flange’s structural integrity. The welding process helps to distribute stress evenly, minimizing the risk of leaks.

WHAT SIZES OF WELD NECK FLANGES ARE AVAILABLE?

Cole Industrial supplies weld neck flanges in a wide range of sizes, from small-diameter flanges suitable for low-capacity systems to larger flanges for high-volume applications. Please contact us for specific size availability.

HOW DO I CHOOSE THE RIGHT WELD NECK FLANGE FOR MY APPLICATION?

Choosing the right weld neck flange depends on factors like pressure rating, temperature requirements, and the materials used in your piping system. Our experts at Cole Industrial can help you select the best weld neck flange to suit your specific needs.